S2/S4 FIBERGLASS

- Home

- S2/S4 FIBERGLASS

Our company’s high-strength fiberglass belongs to the magnesium-alumina-silicate glass system. In comparison to C glass fiber, it exhibits 30-40% higher tensile strength and 15-20% higher modulus of elasticity. It can withstand temperatures of up to 900°C and continuous cycles at temperatures up to 650°C. Due to its high elongation at break, it has 10 times the fatigue resistance and excellent impact resistance. Furthermore, it possesses high aging, corrosion resistance, and quick resin wet-out properties.

1. S2 Glass: This type of fiberglass yarn is known for its high strength and stiffness relative to standard E-glass. It’s often used in applications requiring improved mechanical properties, such as aerospace, military, and sporting goods.

2. S4 Glass: S4 glass is less common than S2 and has a composition that provides even higher tensile strength and stiffness. It’s used in specialized high-performance applications where these characteristics are critical.

These materials are made by pulling molten glass into thin strands that are then woven into yarn. The yarn can be used alone or as a reinforcement in composite materials, providing significant strength enhancements without adding much weight.

Fiberglass roving is a collection of continuous, untwisted strands of fiberglass, and it is a key material used in the production of composite materials. S2 and S4 fiberglass rovings are specific types that offer enhanced properties compared to more commonly used types like E-glass.

S2 Glass Roving:

– Strength and Durability: S2 glass roving is known for its high strength and impact resistance, making it suitable for products that must withstand high loads or impact forces.

– Applications: Commonly used in aerospace, automotive, and sporting goods, where its superior mechanical properties can be leveraged to create lighter, stronger components.

S4 Glass Roving:

– Superior Properties: S4 glass roving takes the characteristics of S2 glass a step further, offering even higher tensile strength and stiffness.

– Specialized Uses: Due to its exceptional properties, S4 is ideal for advanced applications in the aerospace and defense sectors, particularly where performance under extreme conditions is critical.

Manufacturing Process:

– Both S2 and S4 glass rovings are made by drawing molten glass through bushings to form continuous strands. These strands can be used directly or further processed into fabrics or mats for composite applications.

Benefits:

– The use of S2/S4 glass roving in composites results in materials that are not only lighter and stronger but also have superior thermal and acoustic insulating properties. This makes them an excellent choice for a wide range of high-performance applications.

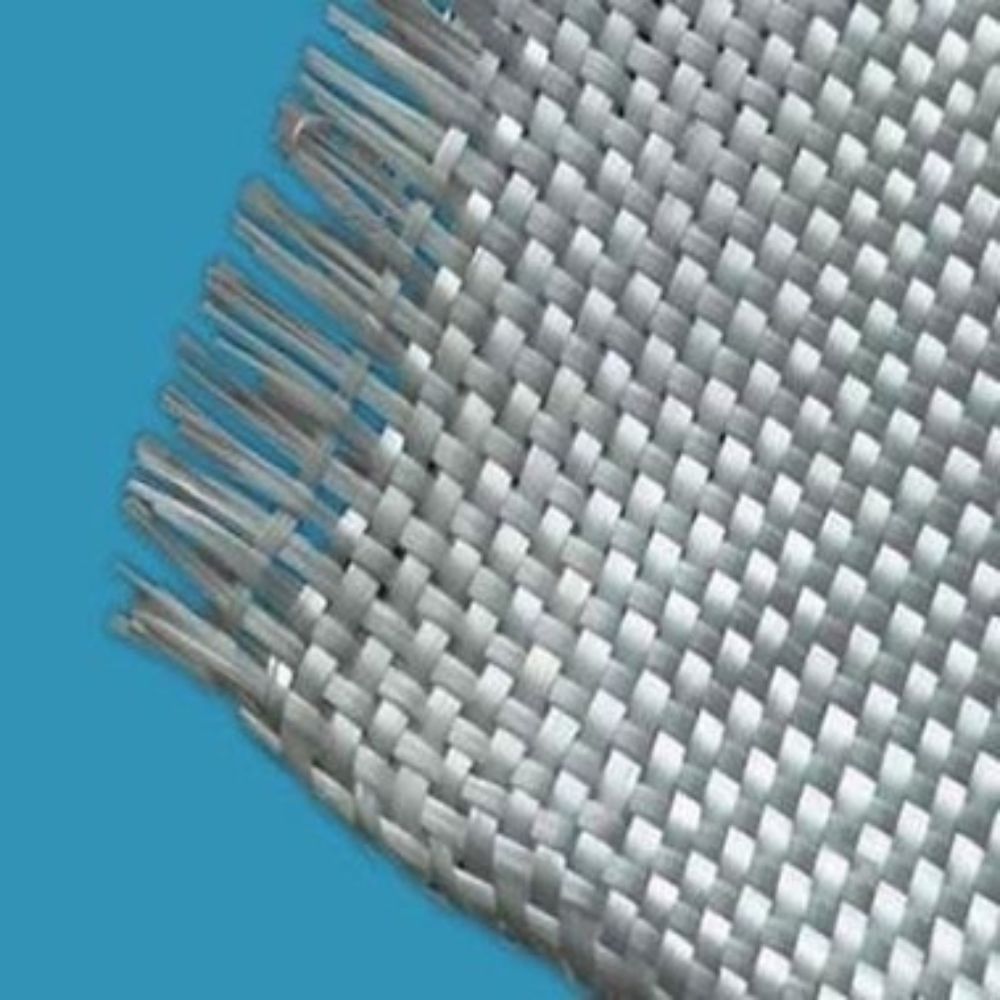

S2 and S4 fiberglass fabrics are advanced materials used predominantly in industries requiring high-performance composites. These fabrics are woven from S2 or S4 glass fibers, which are known for their superior mechanical properties compared to traditional E-glass. The primary distinction between S2 and S4 fiberglass lies in their mechanical strength and stiffness, with S4 being the stronger and stiffer of the two.

Applications of S2/S4 Fiberglass Fabric:

1. Aerospace and Aviation: For components that must withstand high stress while maintaining light weight.

2. Marine Industry: In boat hulls and other parts where strength, durability, and resistance to water are necessary.

3. Sports Equipment: Used in the manufacturing of high-strength yet lightweight items like hockey sticks, bike frames, and surfboards.

4. Automotive Industry: For high-performance components that benefit from reduced weight without sacrificing strength.

Benefits of S2/S4 Fiberglass Fabric:

– High Strength and Stiffness: Significantly stronger and stiffer than traditional fiberglass fabrics, leading to enhanced performance.

– Lightweight: Offers a remarkable strength-to-weight ratio, crucial for many modern engineering applications.

– Corrosion Resistance: Resists various chemicals and water, making it suitable for harsh environments.

– Thermal Stability: Maintains integrity over a range of temperatures.

These properties make S2/S4 fiberglass fabrics ideal for advanced composites where traditional materials might fail to deliver the required performance.

S2/S4 fiberglass chop strands are advanced composite materials known for their exceptional strength and stiffness, significantly outperforming traditional fiberglass.

These strands provide enhanced impact resistance, thermal stability, and are inherently corrosion-resistant, ensuring durability in harsh environments. Their lightweight nature makes them ideal for high-performance applications across aerospace, automotive, and sports equipment industries.

As critical components for products demanding robustness without added weight, S2/S4 chop strands facilitate innovative design and functionality.