Accessories For Composites

- Home

- ACCESSORIES

Introduction:

Discover the essential role of Peel Ply in composite manufacturing. As a versatile release fabric, Peel Ply plays a crucial role in achieving high-quality composite surfaces.

Benefits:

Peel Ply offers several benefits to composite manufacturers. Its textured surface creates a bond-ready finish, promoting better adhesion between layers. Additionally, Peel Ply facilitates easy removal, leaving behind a clean and smooth surface that requires minimal finishing.

Applications:

Peel Ply finds extensive use in various industries, including aerospace, automotive, marine, and sporting goods. It is commonly applied in the fabrication of composite parts such as aircraft wings, automotive components, boat hulls, and surfboards.

Quality Assurance:

At the heart of Peel Ply’s effectiveness is its ability to ensure consistent and reliable results. By providing a uniform surface finish and promoting resin flow, Peel Ply helps maintain the integrity and quality of composite structures.

Conclusion:

In conclusion, Peel Ply serves as an indispensable tool in composite manufacturing, offering enhanced surface preparation, improved adhesion, and superior quality control. Explore its versatility and benefits to elevate your composite projects to new heights.

Discover the versatility and functionality of Breathing Cloth, a specialized material designed for a multitude of applications. Engineered to provide superior breathability and airflow, Breathing Cloth offers exceptional comfort and performance in various industries.

In the realm of apparel, Breathing Cloth is prized for its ability to regulate temperature and moisture, keeping the wearer cool and dry even in the most demanding conditions. Its lightweight and breathable construction make it ideal for activewear, sportswear, and outdoor apparel, providing unparalleled comfort and mobility.

Beyond fashion, Breathing Cloth finds extensive use in medical and healthcare applications. Its breathable properties make it ideal for wound dressings, surgical drapes, and other medical textiles, ensuring optimal airflow and moisture management for enhanced patient comfort and healing.

In industrial settings, Breathing Cloth serves as a reliable filtration medium, effectively capturing dust, particles, and contaminants while allowing for efficient airflow. Whether used in HVAC systems, air filters, or industrial processes, Breathing Cloth delivers superior filtration performance and air quality.

With its diverse range of applications and superior performance characteristics, Breathing Cloth is the go-to choice for industries seeking breathable, comfortable, and reliable materials.

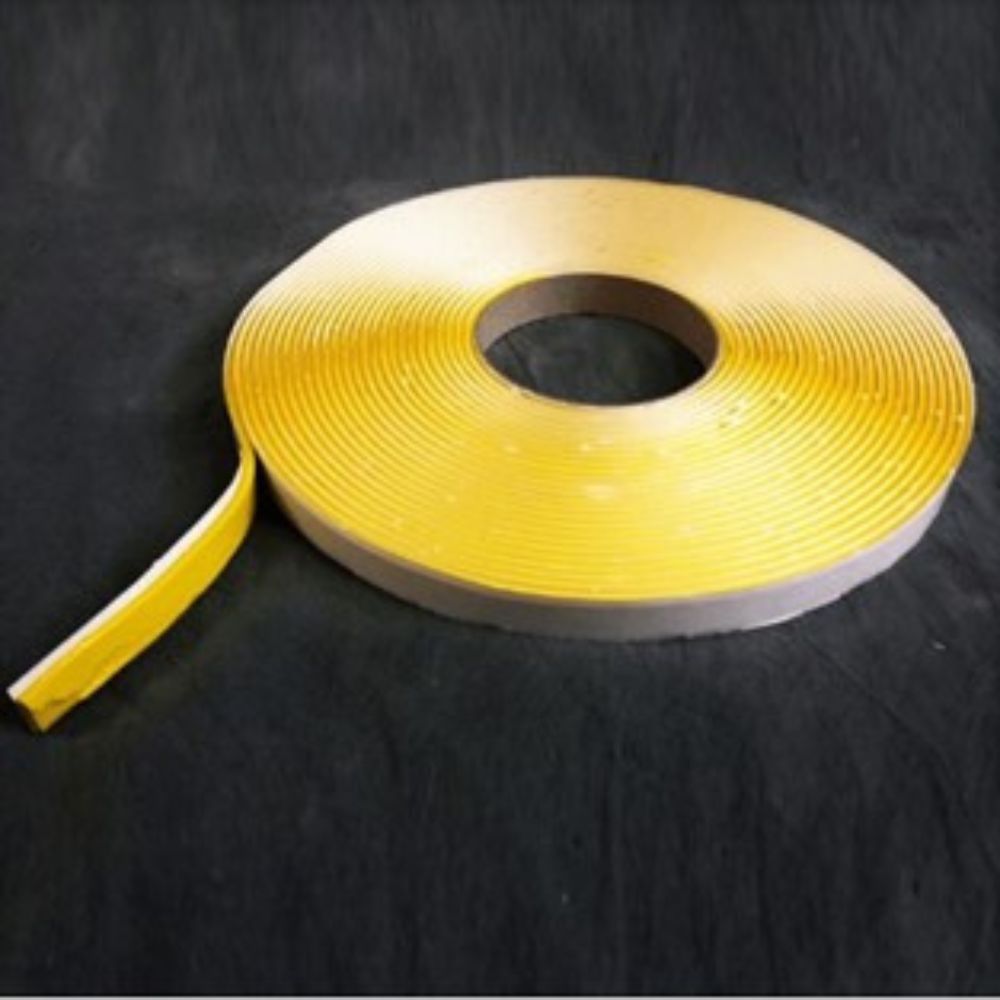

Sealant tape is typically used when an airtight seal is required and will adhere to most surfaces. It is commonly used in the composite manufacturing process for both temporary and permanent vacuum bagging. The tape features an aggressively tacky, solid extrusion that provides a strong hold for many sealing applications, such as sealing between glass, metal, wood, and many plastics. This butyl tape is permanently tacky and offers exceptional resistance to cold flow and low moisture vapor transmission, ensuring long-lasting performance.

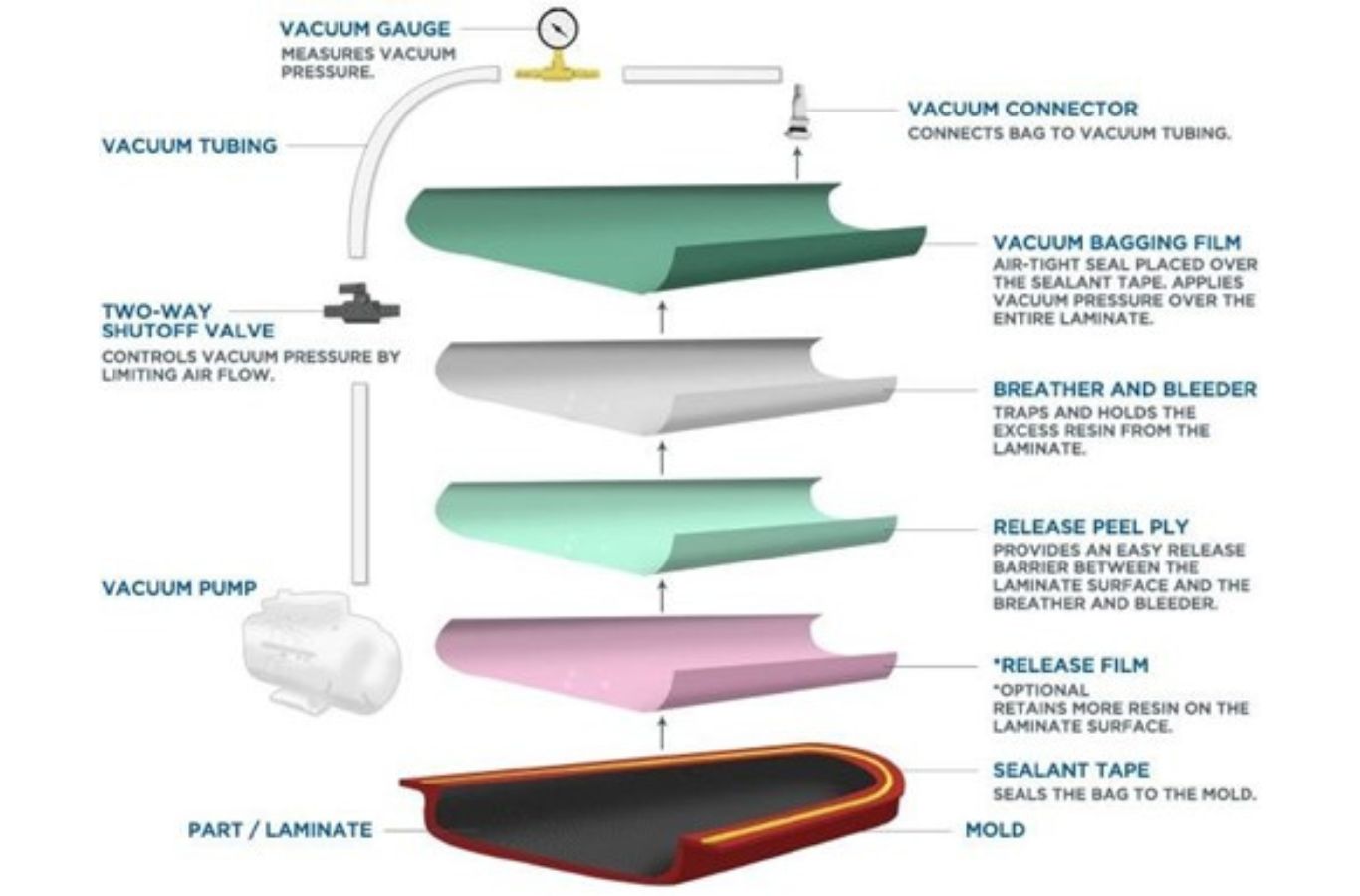

Discover the ultimate solution for composite manufacturing with our Vacuum Bagging Film. Engineered to perfection, our film offers unmatched performance and reliability in vacuum bagging applications.

Enhanced Performance:

Our Vacuum Bagging Film is designed to optimize the vacuum bagging process, ensuring consistent pressure distribution and air removal for superior composite consolidation. With its high-strength construction and advanced materials, our film delivers exceptional performance in demanding environments.

Versatile Applications:

From aerospace components to marine vessels, our Vacuum Bagging Film is suitable for a wide range of composite manufacturing applications. Whether you’re creating lightweight structures or reinforcing existing materials, our film provides the versatility and durability you need to succeed.

Easy to Use:

Featuring a user-friendly design, our Vacuum Bagging Film is easy to handle and apply, saving you time and effort in the manufacturing process. With its reliable performance and seamless integration, our film streamlines production and ensures consistent results every time.

Trust in Quality:

At our company, we pride ourselves on delivering top-quality products that meet the highest industry standards. With our Vacuum Bagging Film, you can trust in the quality and reliability that will take your composite manufacturing to the next level.